Offset Machines

Offset printing is the most popular technique for commercial printing. It has been around since the 20th century, helping businesses produce stationery, leaflets, brochures, magazines, and cards in bulk. Also called offset lithography, commercial offset printing is also used for labelling packages such as boxes or cartons.

This is a process used for printing on a flat surface, using plates. An image is transferred to an offset plate which is chemically treated so that only image areas (such as type, colours, shapes and other elements) will accept ink. Water and ink are applied to the plate.

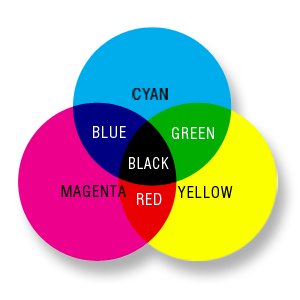

Because of the chemical treatment, ink only “sticks” to the image areas, which reject the water. Areas without images reject the ink. The images with ink are transported then from the plate to the surface of the blanket. The task of printing blankets that are made of special multi-layer rubber is to convey the image or illustration to the paper and this is repeating on every cardboard that passes through the printing machine. When we print full colour job the cardboard is overprinted four times on four separate printing units with different colours.